Wing Overhaul, Modification, and Upgrades

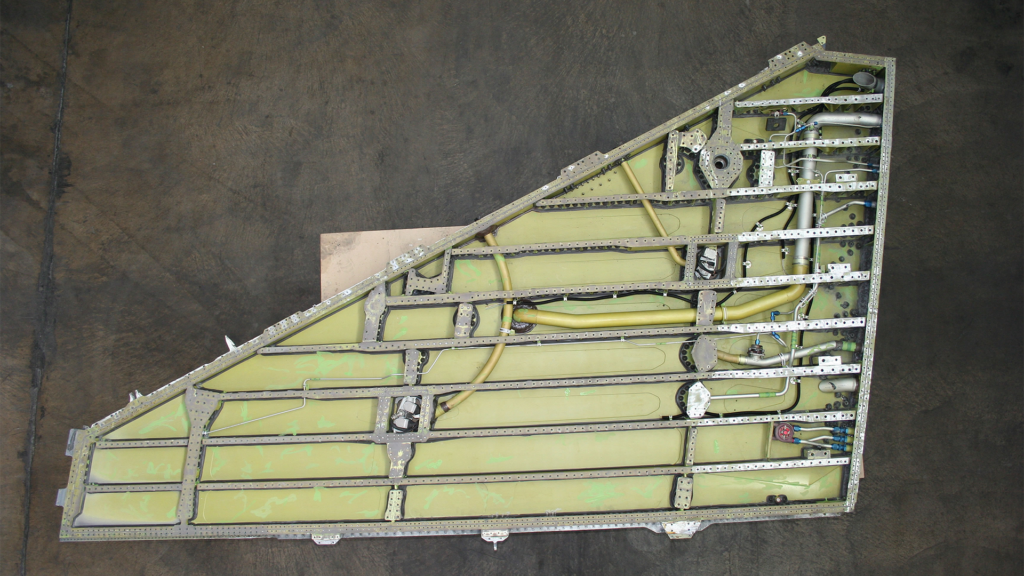

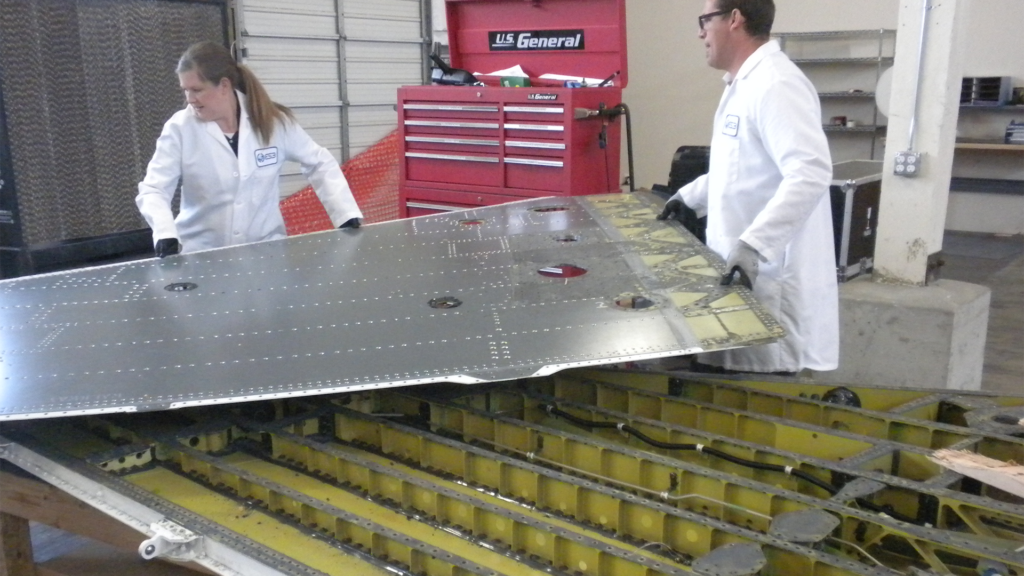

ES3 provides F-16 wing overhaul, removing upper and/or lower wing skins. All wings receive structural integrity inspections and necessary repairs. Wings are cleaned, re-skinned and re-sealed to original factory specifications.

ES3 staff includes certified wing overhaul technicians and production engineers who have completed hundreds of wing overhauls. ES3’s technical lead for F-16 repairs is Rob McCowin, former US Air Force F-16 Engineer and Manager of USAF’s F-16 Airframe Structural Integrity Program (ASIP).

ES3 provides F-16 wing overhaul, removing upper and/or lower wing skins. All wings receive structural integrity inspections and necessary repairs. Wings are cleaned, re-skinned and re-sealed to original factory specifications.

ES3 staff includes certified wing overhaul technicians and production engineers who have completed hundreds of wing overhauls. ES3’s technical lead for F-16 repairs is Rob McCowin, former US Air Force F-16 Engineer and Manager of USAF’s F-16 Airframe Structural Integrity Program (ASIP).

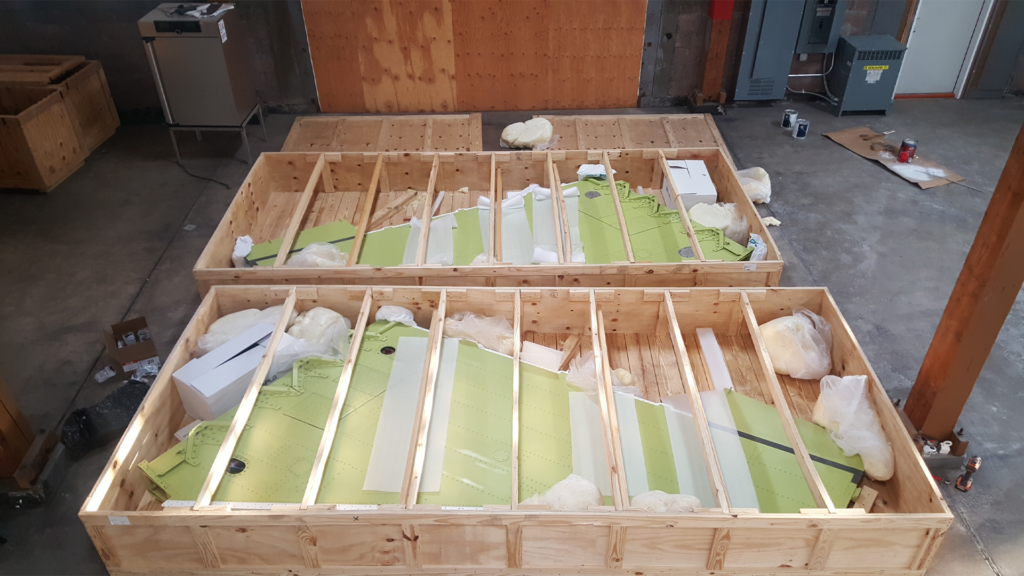

At our 120,000 square foot overhaul facility in Clearfield Utah, ES3 has the necessary tools and fixtures for AS9100 controlled and USAF certified wing and other structural overhauls. ES3’s in-house tools, fixtures, and capabilities includes:

- Milling tool and vertical fixture to ensure matchup of overhauled wing with aircraft.

- Match drill fixture to ensure proper hole drilling of new skins.

- Non-destructive Inspection (NDI) process documents and worksheets

- Configuration controlled

This time-lapsed video shows our staff installing a top skin over a newly refurbished and configuration modified F-16 wing.