Navy EPaS

The US Navy EPaS (Equipment Procurement and Sustainment) contract N6833519D0061 was awarded to ES3 in 2019 and has a five-year period of performance with three 1-year options. The EPaS Navy contract vehicle supports USN Fleet Readiness Centers with depot level maintenance operation, various equipment procurement and equipment sustainment necessary to meet fleet aircraft schedules and obtain solutions for product lines challenged by obsolescence issues—materially-aged, and technologically-dated equipment that is negatively impacting the command’s capacity to support 4th and 5th generation weapon systems.

The EPaS contract covers a range of functional areas that include (but are not limited to) Ancillary Equipment, Blasting and Test Equipment, Coating Equipment, and Wet Processing Equipment.

ES3 is available to support the Additive Manufacturing Equipment functional area. This functional area includes but is not limited to equipment required for joining or adding materials through extruding or jetting. Examples include, but are not limited to, 3D printers, cold spray, flame/metal spray, and hybrid manufacturing systems.

ES3 is one of five contractors available to support the Ancillary Equipment functional area. This functional area includes support equipment necessary to provide full functionality of the process and equipment to provide gas, air, solid particulates, fluid handling and treatment. This includes functions of general millwright and other support necessary to install the equipment. This includes all material, labor, and transportations to provide, install a complete usable system including utilities, training for operation, warranty repair. Examples include, but are not limited to, deionized (DI) water conditioning system, pumps, compressors, Reverse Osmosis (RO) filters, filters, air scrubbers, cooling towers, air dryers, vacuum pumps, breathing air, industrial controls, control software, remote networking systems.

ES3 is the sole source contractor for the Blasting & Sanding Equipment functional area. This functional area includes equipment to remove coatings prior to wet processing, plating, coating, and painting. Additionally, this functional area includes equipment for working hardening surfaces (i.e. peening).

ES3 is the sole source contractor for the Coating Equipment functional area. This functional area includes all equipment required to provide coating/final finish for painting, powder coating, and ion plating for corrosion resistance, ease of cleaning procedures, increased surface hardness, etc. Types of equipment includes but are not limited to zinc, nickel, and chrome plating tanks, paint booths, and shot peening/sand blast booths.

ES3 is also the sole source contractor for the Wet Processing Equipment functional area. This functional area of equipment provides final finish for plating various metals. It includes all equipment required to coat/finish material in order to provide priming, conversion, finish surface, corrosion resistance, cleaning procedures, and increased surface hardness.

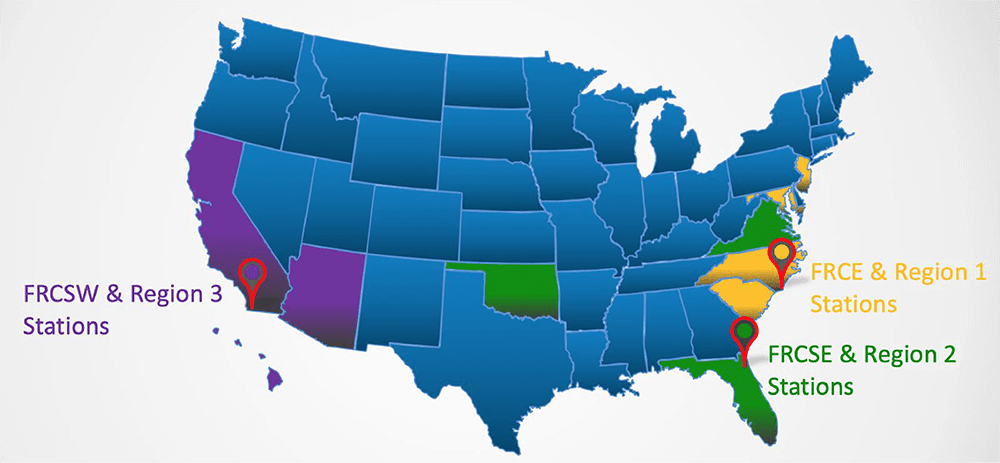

The EPaS contract covers the following US Navy Fleet Readiness Centers:

Region 1: Fleet Readiness Center East

- Marine Corps Air Station, Cherry Point, North Carolina

- Marine Corps Air Station, New River, North Carolina

- Marine Corps Air Station, Beaufort, South Carolina

- Joint Base McGuire-Dix-Lakehurst, New Jersey

- Aviation Support Equipment, Solomons Island, Maryland

Region 2: Fleet Readiness Center Southeast

- Naval Air Station, Jacksonville, Florida

- Cecil Commerce Center, Jacksonville, Florida

- Naval Station, Mayport, Florida

- Naval Air Station, Key West Florida

- Tinker Air Force Base, Oklahoma City, Oklahoma

- Naval Air Station Mid-Atlantic, Norfolk, Virginia

Region 3: Fleet Readiness Center Southwest

- Naval Air Station, North Island, California

- Naval Air Station, Point Mugu, California

- Naval Air Facility, El Centro, California

- Naval Air Station Lemoore, California Marine Corps Air Station Miramar, California

- Marine Corps Air Station, Camp Pendleton, California

- Marine Corps Air Station, Yuma, Arizona

- Marine Corps Air Station, Kaneohe Bay, Hawaii

For more information about the ES3 EPaS contract, please contact:

Ed Moffett

ES3 Business Development

801-926-1150

PSS.info@es3inc.com